The aluminium foil element of the ribbon microphone is only lightly tensioned, causing resonance at very low frequencies. When digital recording became the order of the day, ribbon microphones made a major comeback because high-frequency transfer loss was no longer an issue. Its ability to record fast transients accurately without adding upper-range resonances became again a very positive attribute.

Articles about the ribbon microphone dates back as far as 1931. Most of the early publications were authored by Harry F. Olson who patented the ribbon microphone. Few publications besides those by Olson can be found about the ribbon microphone, but plenty of patents relating to the ribbon microphone are freely available. A selection of those patents is discussed in the paragraphs to follow.

Olson 1932

Harry Olson filed the first patent for the ribbon microphone in 1931 and the patent was awarded on 25 October 1932 with the title “Apparatus for converting sound vibrations into electrical variations”.

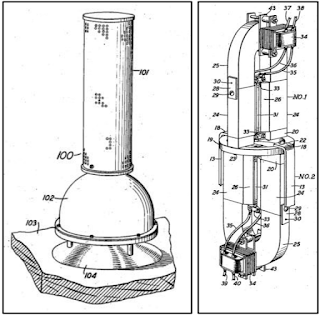

The patent illustrations are of very sturdy mechanical designs as illustrated in picture below:

It describes the ribbon as a relatively small item that is supported in such a way that it resembles

the motion of a particle in free air. A device of this nature is classified as a velocity microphone.

The combination of mechanical parts surrounding the ribbon is called a baffle. The size of the

baffle around the ribbon is calculated according to the highest frequency that the microphone is

designed for. The baffle should be designed so that the path length from the front of the ribbon to

the rear of the ribbon is half the wavelength of the required frequency. Picture below provides a graph

from the patent to illustrate the effect of the baffle size on the frequency response of the

microphone.

The ribbon is made of conducting material that is light in weight and that has low elasticity, for

example aluminium foil. The ribbon must not be stretched tightly between its supports. It is crimped

in order to suspend it rather loosely between its supports to promote flexibility along its whole

length. The supports are made of non-ferro-magnetic conducting material, but it is electrically

isolated from the ribbon by non-conductive material. The two signal wire leads are electrically

connected to the two ends of the ribbon. The light weight and small restoring force of the ribbon

causes its natural vibration frequency to be below the audible range. Tests that were done before

the patent submission had shown that a natural vibration frequency of approximately 10Hz

produced the most desirable results. The patent states that “When a diaphragm of small mass is

suspended in this manner its mechanical reactance is small compared to the impedance of the air.

In other words its mass reactance is negligible over a large frequency range compared to the

acoustic resistance of the air which it displaces.”

The ribbon is suspended in the air gap between two poles of a magnet in such an orientation that

its surfaces are parallel with the magnetic force lines. The magnet can be a permanent magnet or

an electromagnet. The gap between the ribbon and the magnet poles are kept to a minimum to

prevent the leakage of air around the ribbon, but the gaps must still be sufficient to prevent

frictional contact between the ribbon and the magnet. The patent suggests an air gap of 5.6mm

with the ribbon slightly narrower. The ribbon cuts the magnetic field lines while moving in the air

gap between the poles because of the sound pressure variations across it. This causes an electromotive force that is proportional to its movement. The electromotive force can be amplified

with suitable electronic equipment.

The magnetic pole pieces with its supporting structure forms the baffle. The baffle increases the

path length from the front to the back of the ribbon. The length of this path has an influence on the

response of the microphone. The paths around the top and bottom supports of the ribbon are

shorter than the paths around the baffle, but its effect is relatively small because it influences only

a small part of the ribbon. The clamping structure that secures each end of the ribbon is made of

non-magnetic material (ex. copper or brass if it is made from metal). Although it is desirable to

make the ribbon as light as possible, it is sometimes necessary to vary its thickness in order to

increase its efficiency within the particular baffle setup. The movement of the ribbon is caused by

the phase difference of the sound wave between the front and back of the ribbon. The phase

difference is determined by the distance that the sound wave has to travel around the baffle from

the front to the back of the ribbon. The greatest phase difference occurs when the path length

around the baffle is half a wavelength of the sound wave under question. Olson provides a helpful

visual representation of this effect in his patent. Picture below shows a horizontal cut through the

microphone and a sinusoidal representation of a sound wave. If the path length A-B around the

baffle is plotted as E-F on the axis of the sound wave, then the pressure difference between points

A and B on the ribbon will be equal to the sum of C-E plus D-F.

The sound intensity at the opposite sides of the baffle is virtually the same for all wavelengths that

are longer than twice the distance around the baffle. At wavelengths shorter than this, the intensity

on the approaching side of the ribbon increases and the intensity at the retreating side decreases.

The reasoning follows that the pressure difference across the ribbon is proportional to the

frequency as long as the distance around the baffle is less than half the wave length. Due to the

nature of the design the ribbon microphone exhibits very directional characteristics. Sound waves coming from an angle will produce less of a pressure difference across the ribbon. A sound wave

directly from the side will produce virtually zero pressure difference. The pressure difference can

be calculated with simple trigonometry rules.

An alternative design is also provided in the patent. The alternative design does not make use of a

ribbon, but of a lightweight diaphragm. This design is however overly complicated and will not be

discussed further.

Olson & Weinberger 1933

In 1933 Olson, in cooperation with Julius Weinberger, filed a patent that made use of a

combination of the pressure gradient (velocity) ribbon microphone and a pressure component

microphone to achieve unidirectional operation. Unidirectional operation is desirable in order to

improve the ratio of the sound source relative to the sound reflections in the room. The patent

achieved its purpose through the use of a normal ribbon (as in the 1931 patent) assembled in

series with a modified ribbon. The modified ribbon was adapted to act as a pressure microphone

by enclosing the back of the ribbon. The normal and modified ribbons are working in phase for

sounds generated in front of the microphone, but are out of phase for sounds originating from the

rear side of the microphone. This patent illustrates the influence of the baffle in the extreme case of

making the baffle infinitely large by enclosing the rear side of the ribbon completely.

Anderson 1937

Leslie Anderson added electronics to Olson and Weinberger‟s unidirectional microphone to file a

patent in 1937. The electronics made it possible to adjust the phase differences between the

two ribbons, thereby making it possible to adjust the directionality of the microphone from the

mixing desk.

Ruttenberg 1938

In 1938 Samuel Ruttenberg filed a patent to address one of the imperfections of the ribbon

microphone. When speaking close to the microphone, the low frequencies are over

emphasised because the higher frequencies are attenuated. The high frequency attenuation

happens because different sections of the ribbon move out of phase. Thus one section cancels out

the electrical current that is generated during vibration of another section. The sections move out of

phase due to the fact that the ribbon is longer than the wavelength of the higher frequency sound

waves. Ruttenberg addressed this problem by designing a special housing for the microphone

which closes up the rear of the microphone with an adjustable shutter. When closing up the rear of

the microphone, its characteristics are changed from that of a velocity microphone to that of a

pressure microphone because the sound wave does not have access to the rear of the ribbon. This

idea clearly borrows from the same principles than Olson and Weinberger‟s patent on the unidirectional microphone. The microphone‟s operation in pressure mode tends to minimise the

effect of high frequencies being attenuated. This patent clearly illustrates that tampering with the

physical surroundings of the ribbon microphone, does have a distinct influence on its operation.

Bostwick 1938

Telephone conferencing has been around for longer than one would expect. In 1938 Lee Bostwick

already addressed the problem of feedback between speaker and microphone during

teleconferencing. He filed a patent for a device making use of two ribbon microphones and a

loudspeaker. The device is constructed with a loudspeaker facing downwards onto a deflector

underneath that reflects the sound waves in a horizontal direction toward the conference

attendees. Two ribbon microphones are fitted perpendicular on top of each other, both on top of

the loudspeaker. Because of its directionality, the ribbon microphones are insensitive to the sound

waves emanating from below it, but are sensitive to the voices of the conference attendees around

the table.

Bostwick‟s teleconference solution

Olson 1940

In 1940, Harry Olson filed a patent for an improved version of the 1933 unidirectional microphone . Olson discovered that he can design a unidirectional microphone with a single ribbon instead

of the dual-ribbon method used previously. Furthermore, this microphone could be easily changed

from unidirectional to bidirectional, to non-directional operation. The method of achieving this was

to place a pipe structure (resemblance of a smoking pipe) behind a single ribbon. The pipe ends in

a labyrinth that is filled with a soft fabric acting as acoustic resistance. The pipe has shutters that can be opened or closed to achieve the desired results, i.e. shutters open allows bidirectional

operation, shutters partly closed enables unidirectional operation and shutters completely closed

constrains it to non-directional operation. This patent illustrates once again the influence of the

surroundings of the ribbon on its operation.

Anderson 1942

Leslie Anderson built upon Olson‟s 1933 patent by filing a patent in 1942 about the magnetic

equalization of sensitivity in a unidirectional microphone. It is fundamentally an improvement

on Olson and Weinberger‟s design by adding a mechanism to adjust the magnetic fields for the two

ribbons and by changing the shape of the pole pieces in such a way that it is possible to vary the

flux density of one air gap relative to the other. This patent indicates support for Olson and

Weinberger‟s idea of modifying the baffle in order to change the operation of the microphone for a

specific purpose.

Rogers 1942

Ernest Rogers filed a patent in 1942 for a microphone with selective discrimination between sound

sources . He claimed that the microphone can be used to determine the direction of a sound

source. The microphone receives sound waves approaching the microphone straight-on, but

attenuates sound waves approaching the microphone from an angular displaced direction. The

construction of the microphone is basically four ribbon microphones assembled in an X-pattern.

The ribbons are connected to a mixing circuit in such a way that the phase relationship between

the ribbons can be adjusted. By adjusting the phase relationship, the microphone can be tuned so

that the phases of sound waves from a certain direction cancel each other out, while the phases of

sounds waves from another direction will add to each other.

Olson 1946

The ribbon microphone inherently has a directivity pattern. Olson filed a patent in 1946 to

combine two ribbon microphones in a perpendicularly fashion in order to get a microphone that has

a 360° pattern on the horizontal plane. This microphone would be ideal for use in orchestras

for example, recording all the instruments around it, but attenuating sound waves reflecting from

the ceiling and from the floor. Part of the idea is borrowed from Bostwick‟s teleconferencing

microphone discussed earlier.

Anderson 1947

Anderson‟s patent application in 1947 was filed as an improvement on Olson‟s 1931 design.

According to Anderson, Olson‟s design displayed a considerable drop in output when the distance

around baffle approaches one fourth of the sound wave‟s wavelength. Anderson‟s design claimed

to have a more uniform response over the operating range of the microphone and also to have an enhanced high frequency response compared to the conventional design. This was accomplished

by mounting one or more semi-circular bands behind the ribbon. The bands provide cavities that

are resonant at the frequencies where the enhancements are deemed necessary.